Continuous xRNA Manufacturing

The Future of xRNA Manufacturing

Like many advanced and emerging modalities, xRNA therapeutics rely on traditional batch processing and offline analytics to enable each process step for an investigational drug. With funding from FDA’s Center for Biologics Evaluation and Research (CBER) Advanced Technology Program, and in partnership with MIT, Recipharm Advanced Bio has developed Recimagine™ CPS, an advanced manufacturing and analytics technology platform to match the needs of next-generation xRNA therapeutics, all in a single facility located in the heart of Boston’s biotech hub.

The Building Blocks of Accessible xRNA Therapeutics

While biologics account for only 2% of all prescriptions in the United States, they account for an astounding 46% of annual drug spending. While the specific numbers differ slightly in other markets worldwide, the challenge remains: The promise of advanced biologics is inaccessible to many patients due to their expense.

By combining our continually expanding knowledge hub, digital process development, continuous integrated manufacturing, and sophisticated process analytical technologies (PAT), the Recimagine™ CPS sharply decreases timelines. It runs continuously and is supported by state-of-the-art automation, significantly reducing costs and increasing advanced therapeutic accessibility.

The machine learning-enabled Knowledge Hub becomes more intelligent with every project, enabling increasingly robust predictive control and experimental knowledge

Less than 1 month rather than 6-9 months

High-throughput screening and digital simulation develop parameter targets and suggest experimental plans to optimize the recipe

7-14 days rather than 3 months

The established digital process model informs process analytics controls of the expected results at each stage. Inline analytics monitors progress, ensuring critical quality attributes (CQA) are achieved

Inline PAT capabilities and predictive analytics monitor processes in real time, eliminating the need for CQA-based gating

The Future of Advanced Therapy Manufacturing Is Fast

Recimagine™ CPS combines extensive scientific expertise, AI-enabled technologies, and state-of-the-art process analytic technologies (PAT) to reduce the finished drug product timeline by up to 67%.

Consolidated xRNA Processing Solutions

Recipharm Advanced Bio provides comprehensive xRNA manufacturing solutions under one roof, including plasmid DNA and lipid nanoparticle (LNP) production.

Recipharm Advanced Bio’s flexible xRNA platform is designed to support a wide range of RNA-based therapeutics, ensuring a reliable, scalable approach from preclinical development through commercial production

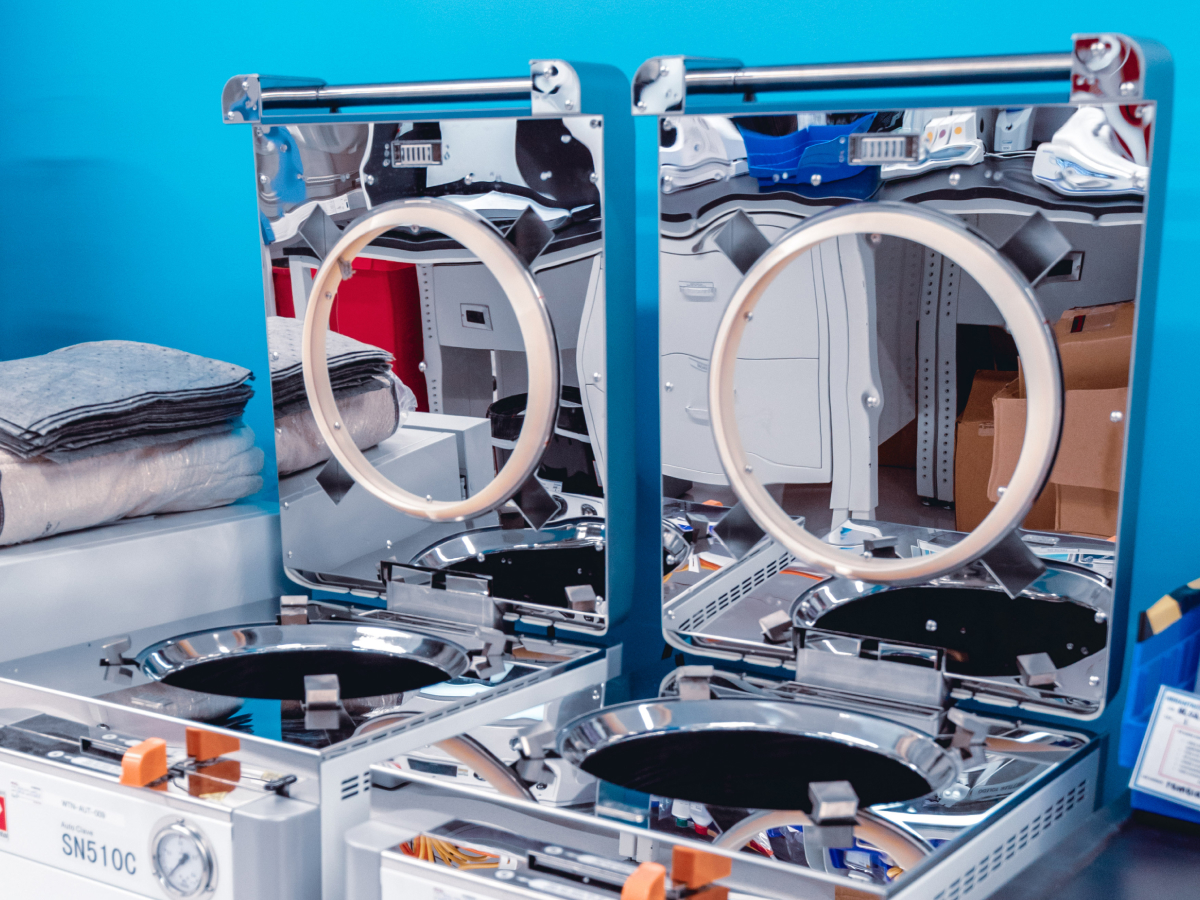

Our facilities and equipment are designed for every phase of your project, scale from 1 to 50g, and utilize a range of mixing technologies

Featured Innovations & Collaborations

xRNA Manufacturing Resources

Advancing Your Program Together

Your program isn’t just another project—it’s a breakthrough in the making. At Recipharm Advanced Bio, we bring deep scientific expertise, innovative thinking, and a problem-solving mindset to every partnership. Whether scaling a complex process, navigating regulatory pathways, or optimizing for commercial success, we’re here to collaborate, adapt, and deliver with excellence.

Let’s push the boundaries of possibility together and bring transformative therapies to patients faster.