Scalable Microbial & LBP Production

Your Partner for Scalable, Cost-Effective Microbial & LBP Production

Leveraging decades of experience, Recipharm Advanced Bio has the expertise to support hundreds of microbial species, facilitating the development, cGMP clinical, and commercial manufacturing of diverse microbial and live biotherapeutic product (LBP). In fact, we proudly support the first commercially approved orally administered microbiota product for Clostridoides difficile infection.

Diverse Microbial & Live Biotherapeutic Product Capabilities

Recipharm Advanced Bio’s experience working with more than 400 species facilitates its flexibility in supporting your LBP throughout its entire lifecycle, from process development to clinical supply to commercial manufacturing.

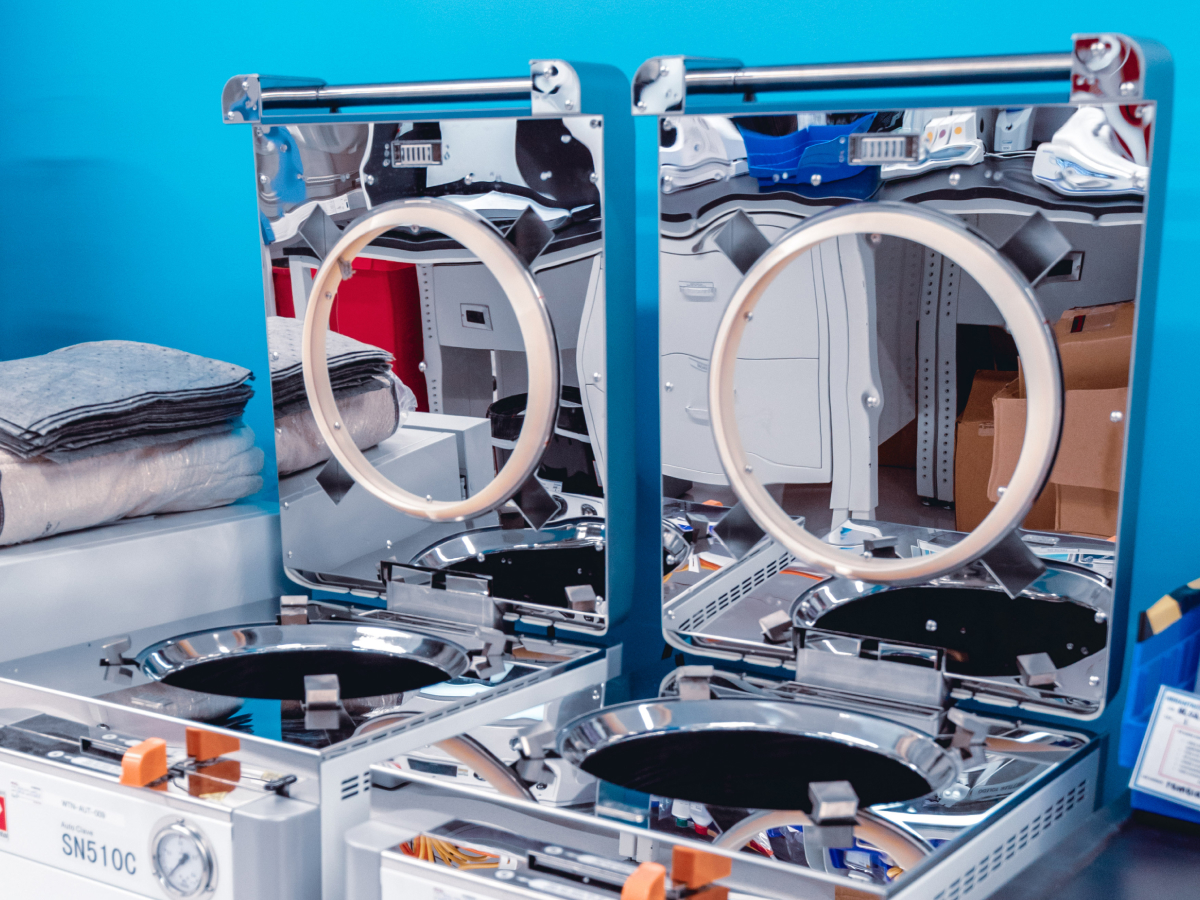

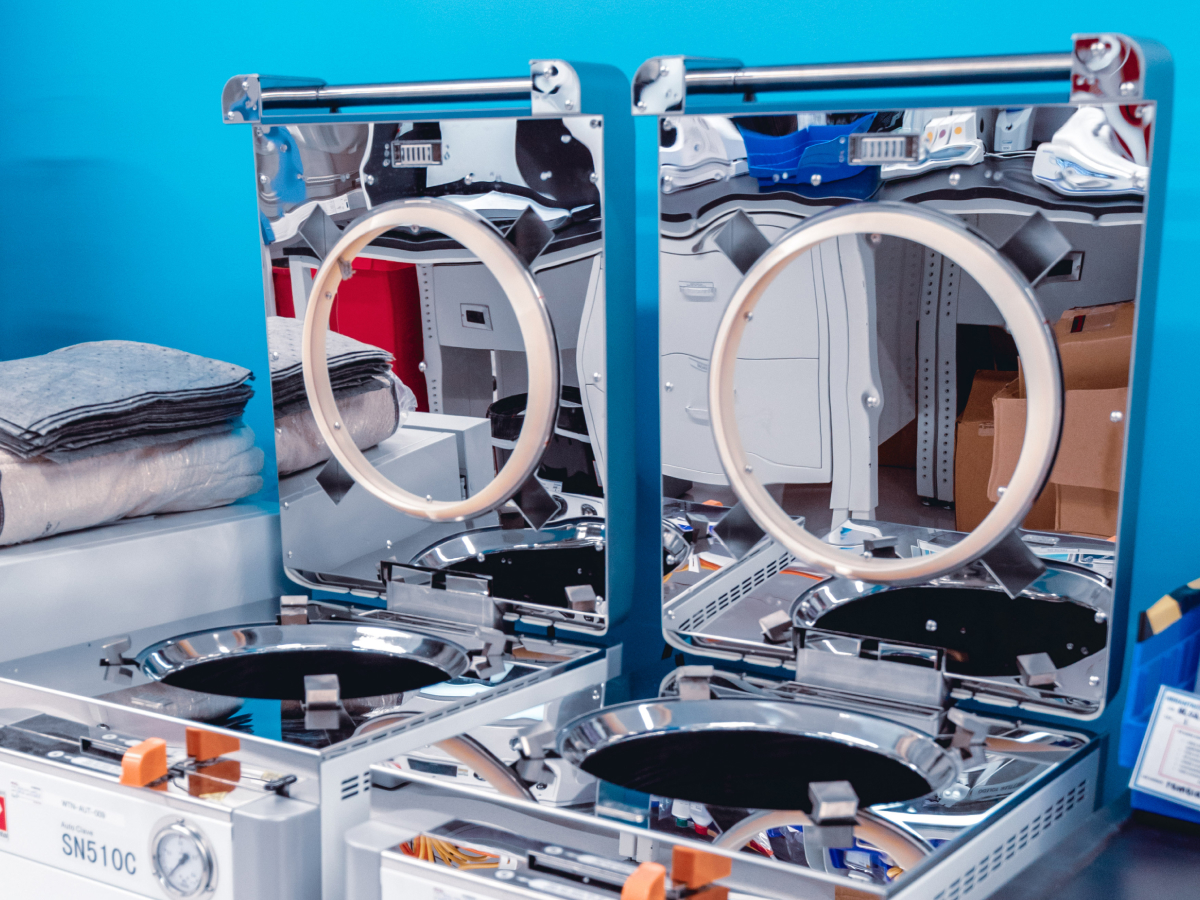

Our clinical and commercial manufacturing facility for LBP drug substances and drug products is built to develop and manufacture advanced biologic therapies, including LBPs that require up to BSL-2 segregation.

- Single strains or multi-strain consortia

- Expert microbial cell banking ensures genetic stability, cell viability, and purity

- Liquid or dried bulk drug substance

- Solid oral dose

- Other drug product finished dosage forms

- Aerobic

- Anaerobic

- Genetically engineered strains

- BSL-2 fungi and spore-forming species

Comprehensive Program Support for Multiple Modalities & Drug Product Formats

We are experienced with aerobic, anaerobic, spore-forming, bacterial, and fungal microbes across 400+ species and 100+ genera. This diverse expertise allows us to support microbial and LBP programs throughout the product lifecycle.

Microbial cell banking

Our approach to microbial cell banking ensures genetic stability, cell viability, and purity. This reflects our dedication to the highest-quality starting materials and stringent regulatory compliance.

Microbial & LBP drug product development

LBP formulations are typically quite challenging given their sensitivity to environmental conditions, potential ramifications of the host microbiome, and the need to maintain viability throughout manufacturing, storage, and administration. With decades of experience, the Recipharm Advanced Bio team is well-positioned to meet these challenges.

Manufacturing, process development & scale-up for multiple modalities

Our purpose-built microbial and LBP process development and production capacity, including single-strain fermentation, consortia, and LBPs requiring up to BSL-2 segregation, meet the complex needs of scaling production while maintaining quality and cost-effectiveness. Additionally, our platform approach speeds process development and de-risks scale-up.

LBP analytical development & quality control

Our dedicated LBP analytical and quality control experts utilize advanced analytical methods for LBP product and process characterization, including new molecular tools for quantifying and identifying LBPs, higher throughput viability testing, and advanced potency assays. We also offer robust release and stability testing for quality control.

Microbial & Live Biotherapeutic Products Resources

Advancing Your Program Together

Your program isn’t just another project—it’s a breakthrough in the making. At Recipharm Advanced Bio, we bring deep scientific expertise, innovative thinking, and a problem-solving mindset to every partnership. Whether scaling a complex process, navigating regulatory pathways, or optimizing for commercial success, we’re here to collaborate, adapt, and deliver with excellence.

Let’s push the boundaries of possibility together and bring transformative therapies to patients faster.