Viral Vector Assets

Comprehensive Development & GMP Manufacturing of Viral Vectors

Viral vectors are essential tools for cell and gene therapy, providing efficient delivery of genetic material into target cells. Developing these complex biologics requires specialized expertise, robust process development, and scalable GMP manufacturing.

ReciBioPharm offers an end-to-end viral vector platform that supports AAV, lentivirus, adenovirus, and other gene therapy vectors with industry-leading expertise in upstream and downstream processing, analytical development, and quality control.

Viral Vector Expertise

Recipharm Advanced Bio specializes in developing and manufacturing a range of viral vectors, ensuring flexibility and scalability for gene therapy and vaccine applications.

Viral Vectors Supported:

- Adeno-associated virus (AAV)

- Lentivirus (LV)

- Adenovirus (AdV)

- Retrovirus (RV)

- Herpes simplex virus (HSV)

- Poxvirus

With state-of-the-art GMP facilities and expertise in plasmid design, process development, and analytical characterization, we provide tailored solutions to meet the specific needs of each vector type.

AAV Platform: Scalable & Optimized for Gene Therapy

Our AAV platform delivers scalable, high-yield AAV production with flexibility in upstream and downstream processing, analytical capabilities, and regulatory compliance.

Upstream capabilities

- Triple-transfection system with multiple cell lines and media optimization

- Advanced transfection reagents and enhancers for improved viral yield

- Process scalability from benchtop (10L) to pilot-scale (50L) production

- Unique HEK293-based production system to ensure consistent viral titer and quality

Downstream capabilities

- Multi-step chromatography purification (affinity capture, ion-exchange polishing)

- Optimized clarification and TFF filtration for impurity reduction

- Full/empty capsid enrichment to maximize potency

Analytical capabilities

- ddPCR, ELISA, and HPLC assays for Z-testing, purity, and potency testing

- AUC and TEM analysis for full/empty capsid characterization

- Mycoplasma, endotoxin, and host cell DNA/protein testing for quality control

With a high-throughput, modular design, our AAV platform is designed for speed, efficiency, and scalability from preclinical studies to commercial production.

Helper Virus Infection & Transduction Processes

Recipharm Advanced Bio has deep expertise in controlled infection and transduction strategies to optimize viral yield and quality for viral vectors requiring helper viruses for replication and gene delivery.

- Helper virus production and banking to support scalable manufacturing

- Controlled MOI (multiplicity of infection) strategies for efficient viral amplification

- Serotype-specific process development for AAV, adenovirus, HSV, and other vectors

- Analytical assessment of helper-virus carryover to ensure regulatory compliance

By leveraging advanced infection and transduction protocols, we enhance vector consistency and optimize transgene expression in final viral products.

Tailored Plasmid Solutions for Viral Vectors

Plasmid DNA is a critical raw material for viral vector manufacturing, serving as the template for vector production. Recipharm Advanced Bio provides custom plasmid design, development, and GMP manufacturing to ensure seamless viral vector programs.

- Packaging plasmids designed for optimal expression and vector assembly

- Serotype-specific plasmid libraries for customized vector development

- ITR integrity optimization to improve AAV genome stability and yield

- Scalable plasmid production from research-grade to GMP-ready and GMP plasmid DNA

Integrating plasmid manufacturing with viral vector production reduces tech transfer risks and improves process efficiency.

Comprehensive Viral Vector Services

We ensure consistent, high-quality viral vector manufacturing by maintaining critical alignment between starting materials, process development, GMP production, and quality control.

- Cell banking solutions to ensure long-term stability and consistency

- Upstream & downstream process optimization for yield and purity improvements

- Tech transfer-ready process designs to support seamless GMP transition

- In-house and outsourced analytical methods aligned between process development & QC

- Comprehensive impurity testing for host cell protein, DNA, and residual plasmid contamination

- Custom assay development to support evolving regulatory expectations

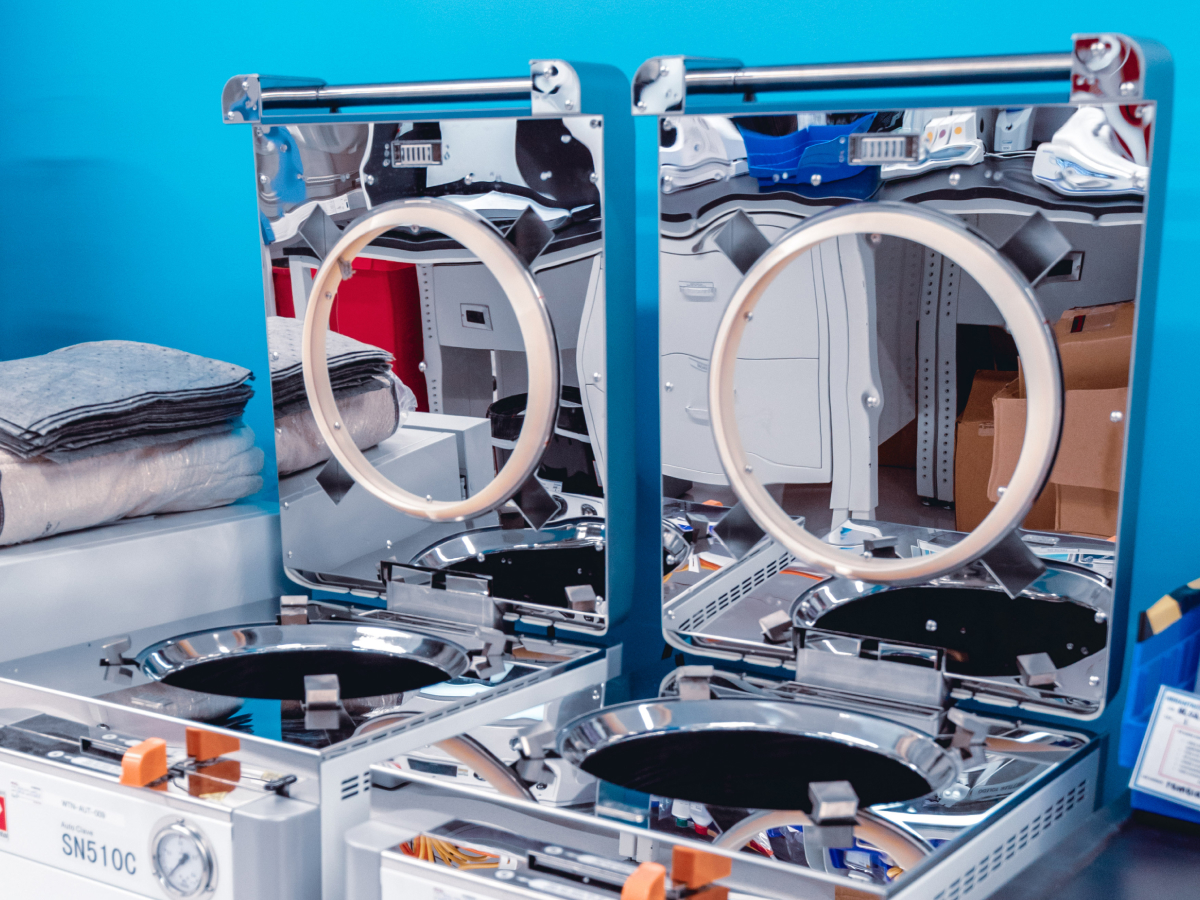

- End-to-end GMP production for clinical and commercial-scale viral vector manufacturing

- 50L–500L drug substance capacity for viral vector production

- 30,000 vials per day sterile fill-finish capacity (2R vials)

- Regulatory compliance with global GMP and ICH guidelines

We ensure consistent, high-quality viral vector manufacturing by maintaining critical alignment between starting materials, process development, GMP production, and quality control.

End-to-End Capabilities Support Integrated Viral Vector Programs

Recipharm Advanced Bio offers fully integrated solutions for viral vector production. Our expertise in process development, scale-up, and GMP manufacturing ensures a seamless pathway for advancing your viral-based therapies.

Our in-house vector design and process development expertise delivers consistently high-quality final pDNA products

Recipharm Advanced Bio’s high-quality cell and virus banks are developed in multiple expansion formats and sizes to meet GMP and client requirements

Recipharm Advanced Bio has extensive experience providing GMP sterile fill-finish services for customers worldwide

Viral Vector Resources

Advancing Your Program Together

Your program isn’t just another project—it’s a breakthrough in the making. At Recipharm Advanced Bio, we bring deep scientific expertise, innovative thinking, and a problem-solving mindset to every partnership. Whether scaling a complex process, navigating regulatory pathways, or optimizing for commercial success, we’re here to collaborate, adapt, and deliver with excellence.

Let’s push the boundaries of possibility together and bring transformative therapies to patients faster.